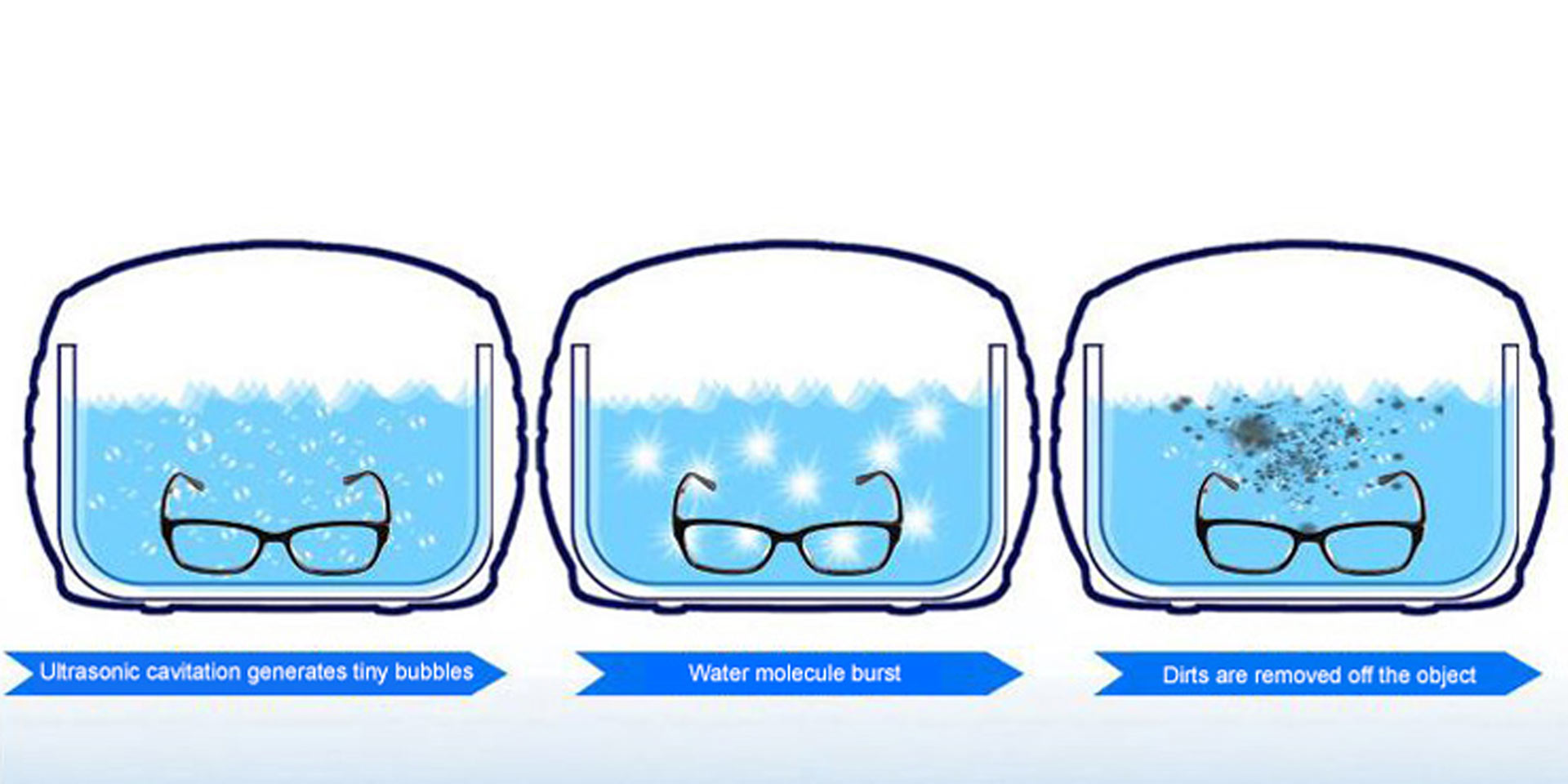

Ultrasonic cleaning resolves high-frequency sound waves transmitted via liquid to scrub clean the surface area of submerged parts. The high-frequency ultrasonic waves, usually 40 kHz, perturb the fluid service of water or solvent and create cavitation of solution molecules.

What is cavitation?

Think bubbles. Cavitation ” bubbles” kind when sonic power produces a gap (or cavity) which obtains caught as a bubble in a liquid option of water or solvent. These microscopic bubbles implode with such force that contaminants adhering to surface areas are displaced. Ultrasonic cleaning machines scrub surface areas clean through implosions of little bubbles.

How Ultrasonic Cleaner Works?

Ultrasonic cleaning appropriates for cleaning a wide variety of products, consisting of metals, glass, rubber, porcelains, and some heavy duty plastics. Ultrasonic cleaning is especially beneficial for eliminating tightly-adhered contaminants from intricate things with blind holes, fractures and recesses. Instances of impurities eliminated via ultrasonic cleaning include dust, dirt, oil, grease, pigments, flux representatives, fingerprints, and polishing substance.

Ultrasonic cleaning systems are commonly used in numerous markets, including clinical tools, auto, aerospace, oral, electronic devices, precious jewelry, and tools. The Best & First * Eraclean Professional Ultrasonic Jewelry Cleaner is my favourite one which uses the most advanced ultrasonic cleaning technology and enables the ultrasound waves to penetrate deep into the slits of jewelry and quickly cleans the surface and deep stains, giving the jewelry a clean-as-new appearance.

Best & First* EraClean Ultrasonic Cleaner for Jewelry Eyeglasses Watches Coins Razors Dentures 12 Ounces(340ML) 45000Hz

The EraClean Ultrasonic Cleaner keeps your favourite pieces clean and shiny, without harsh chemicals. You won’t believe how your items will shine with just water! Just 3 minutes, your items will be polished and ready to wear or use!

The other ideal things for ultrasonic cleaning consist of clinical and surgical instruments, carburettors, firearms, home window blinds, industrial machine parts, and digital tools.

The fluid used in industrial cleaning systems can be either water-based (liquid) or solvent-based. Both types of cleaning solutions have wetting agents (surfactants) to reduce surface area tension and boost cavitation. Liquid cleaning solutions are typically more limited in cleaning up performance, but far better for the environment than solvent cleaning solutions.

The time needed for ultrasonic cleaning relies on the material and soils; however, standard cleaning times vary from 3 to 6 mins. Some precision cleaning products such as electronic devices may need a longer cleaning time. Higher warmth helps loosen dust and chemical bonds faster, so most commercial parts cleaners use heat in the variety of 135– 150 ° F.

It should be noted that ultrasonic cleaning on its own does not sterilize items. In medical applications, sterilization generally follows ultrasonic cleaning as another procedure step.

What is an ultrasonic cleaning machine consist of?

Ultrasonic cleaning equipment consists of complying with standard elements:

Storage tank: The ultrasonic tank holds the fluid and also the products to be cleand.

Ultrasonic generator: The ultrasonic generator transforms A/C electrical energy to an ultrasonic regularity.

Ultrasonic transducer: The transducer transforms the ultrasonic electric signal to power.

What is an ultrasonic transducer?

The ultrasonic transducer is a critical element in an ultrasonic cleaning system. An ultrasonic transducer is a tool that generates sound above the variety of human hearing, usually starting at 20 kHz, likewise referred as ultrasonic resonances.

An ultrasonic transducer contains an active element, a backing and an emitting plate. The majority of ultrasonic cleanrs use piezoelectric crystals as the energetic component. The piezoelectric crystal transforms electrical energy to ultrasonic power with the piezoelectric impact, in which the crystals change shapes and size when they obtain electrical energy.

An ultrasonic transducer’s support is a thick material that soaks up the energy that radiates from the back of the piezoelectric crystal.

The radiating plate in an ultrasonic transducer functions as a diaphragm that transforms the ultrasonic power to mechanical (pressure) wave in the liquid. Hence when the piezoelectric crystal gets pulses of electrical energy, the radiating plate reacts with ultrasonic vibrations in the cleaning service.

What is an ultrasonic generator?

The digital ultrasonic generator is a power supply. It transforms AC electrical energy from a power source such as a wall outlet, to electrical energy appropriate for energizing a transducer at an ultrasonic frequency. In other words, the ultrasonic generator sends high-voltage electric pulses to the transducer.

While the ultrasonic frequency of 40 kHz is without a doubt one of the most generally used for ultrasonic cleaning, some applications do need a lower or higher frequency for ideal results. As an example, more giant, heavily stained products may use a frequency of 20 kHz since this yields bigger, more powerful cleaning bubbles yet fewer bubbles per second. At the other end of the spectrum, some very tiny, delicate products may require greater ultrasonic cleaning frequencies, up to 200 kHz. In general, a higher frequency allows a greater degree of elaborate detail to be cleand.

How do do high-quality ultrasonic cleaner machines differ from low-quality “off-the-shelf” ultrasonic cleaners?

The fantastic reach of the web and overseas makers have brought “off-the-shelf” ultrasonic cleaning machines to the United States. To use the most affordable prices, these suppliers usually gave up high quality. Numerous end users don’t comprehend or identify these sacrifices in quality, so they buy the inexpensive ultrasonic cleaning tank believing it is the same as a U.S.A.-made ultrasonic components washer/ cleaner tank. Regrettably, that could not be further from the fact.

Allow’s check out a few of these sacrifices:

- Piezoelectric transducers can differ considerably in top quality. Because of the crystalline formation nature, transducers will naturally decay in time (3-6 years typically) in their capability to convert electrical energy to mechanical/sound energy. Economic, lower-quality transducers will indeed degeneration much faster than those made with higher-quality crystals. This degradation or decay will considerably alter the cleaning quality of ultrasonic cleaning equipment. When new can usually show decreased cleaning quality in as little as 3-6 months, economical ultrasonic cleaners appear to do well.

- Ultrasonic generators may be made from electrical parts that lack longevity and end-user anticipates. Combined with increased piezoelectric transducer degeneration, these low-quality ultrasonic generator components can gradually result in severe ultrasonic tank cleaning efficiency variants. This cleaning variation subsequently results in extra ditched and revamped components. This stands for not only a major price trouble for an organization, however additionally can trigger the process to fail validation methods and also specs in the medical device, aerospace, and other areas.

3.Low-powered ultrasonic transducers can substantially minimize the expense of an ultrasonic cleaning device. Yet, this sacrifice can also lower cleaning efficiency and endanger the ultrasonic transducer’s capacity to cavitate a service equally. - Storage tank thickness issues. Frequent application of ultrasonic energy to a tank triggers container erosion in time and can erode through the container’s all-time low. Indicators of container disintegration consist of a grey look in stainless steel and pits in the bottom of the storage tank. Low-grade ultrasonic cleaners use a thinner gauge of stainless steel that can show wear in a matter of months.

Leave a Reply